-

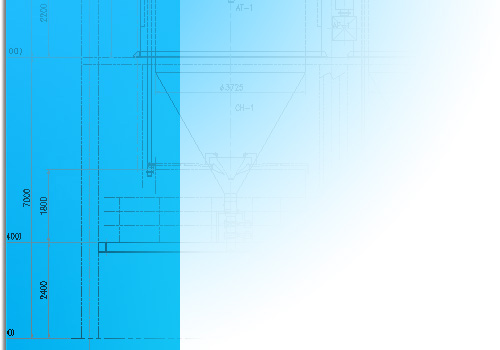

Laboratory use, medium-scale production and large industrial open and closed spray dryers, open and closed spray coolers, fluidized bed systems, exhaust gas coolers and treatment equipment, modifications of all Ohkawara basic model series on customer request. Please do not hesitate to contact us for your special inquiry. Custom Tailored Systems

Custom Tailored Systems -

-

Typical Temperatures Spray Dryers: inlet 150 up to 450 °C, outlet 80 to 100 °C

Spray Coolers: inlet 0 to 20 °C, outlet 50 to 80 °C

Exhaust Gas Coolers, Special Applications: inlet up to 1000 °CSolvent Evaporation Capacities 1 kg/h to several tons per hour Chamber Diameters 300 mm to 10 m Heater Types Electric, steam, gas or oil fired (direct and indirect), combined Applicable Atomizers Various rotary atomizers, 2-fluid nozzles, pressure nozzles, Twin-Jet nozzles, Pulse Jet atomizers Powder Collection Blow-down, take-up, aero cyclones, bag filters, wet scrubbers Options Any

-

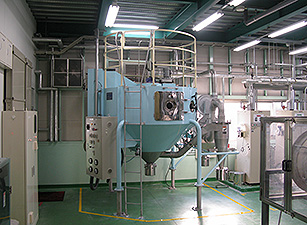

Basic open dryer systems for water-based foodstuff, non-hazardous chemicals, pharmaceuticals and many other feeds. Featuring a HEPA-filter downstream the heater by default, high product purity is always assured. Pilot Series

Pilot Series

-

Typical Temperatures Inlet 150 to 250 °C, outlet 80 to 100 °C Solvent Evaporation Capacities 1 to 170 kg/h (pure water base) Chamber Diameters 300 to 3500 mm Heater Types Electric, steam, gas fired (direct), combined Applicable Atomizers Rotary disc, two-fluid nozzle, pressure nozzle, Twin-Jet nozzle, PulseJet atomizers Powder Collection Blow-down, take-up, aero cyclone Options Air sweeper, bag filter, wet scrubber, CIP, SIP, pneumatic powder conveyor/cooler, air dehumidifier, etc.

-

Developed in close cooperation with TDK's ceramics division, this unique system features an easily removable and washable cloth-made filter chamber as the drying vessel. Impurities due to abrasion and cross-contamination cannot occur. BDP-Series Spray Bag Dryer

BDP-Series Spray Bag Dryer

The single point collection results in high bulk densities, perfect for technical ceramics meant for sintering. HEPA filter included by default.

-

Typical Temperatures Inlet 150 to 200 °C, outlet 80 to 100 °C Solvent Evaporation Capacities 3 to 80 kg/h (pure water base) Bag Diameters 500 to 3700 mm Heater Types Electric, gas (direct) Applicable Atomizers Rotary disc Powder Collection Bag root point Options Sifter

-

Designed for the granulation of fine technical ceramics, the FOC dryers feature a HEPA filter, the patented Ohkawara Low Cap (optimizing the yield at the chamber bottom outlet), an aero cyclone and a bag filter by default. FOC-Series

FOC-Series

-

Typical Temperatures Inlet 150 to 250 °C, outlet 100 °C Solvent Evaporation Capacities 10 to 60 kg/h (pure water base) Chamber Diameters 1200 to 2500 mm Heater Types Electric, gas (direct) Applicable Atomizers Rotary disc, 2-fluid nozzle Powder Collection Low-Cap, aero-cyclone, bag filter Options Sifter

-

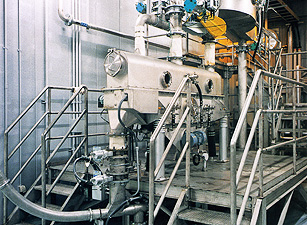

Closed systems use nitrogen as the drying gas and therefore safe drying of inflammable or hazardous feeds is feasible. Furthermore, all solvent is recovered and may be reused. Closed Cycle Dryers

Closed Cycle Dryers

Alternatively open mode operation is possible making these machines a very versatile drying device.

-

Typical Temperatures Inlet 100 to 200 °C, Outlet 70 °C Evaporation Capacities 4 to 28 kg/h (Ethanol base, other solvents feasible) Chamber Diameters 800 to 2500 mm Heater Types Electric (direct and indirect via oil loop) Applicable Atomizers Rotary disc, 2-fluid nozzle, pressure nozzle Powder Collection Blow-down, take-up, aero cyclone, bag filter Options CIP, SIP, split valves for self-contained powder handling

-

Compact combined spray dryer and fluidized bed dryer in one unit. For effective granulation to obtain non-dusting products, quick-dissolving powders, coated particles, to achieve intense powder cooling and for other special applications. FGA-Series

FGA-Series

-

Typical Temperatures Inlet 150 to 250 °C, outlet 80 to 100 °C Evaporation Capacities 5 to 50 kg/h (pure water base) Chamber Diameters 800 to 2000 mm Heater Types Electric, gas (direct) Applicable Atomizers 2-fluid nozzle, air-assisted pressure nozzle Powder Collection Blow-down, fine fraction recycled via aero cyclone

-

The Hypulcon system utilizes a state of the art pulse jet blaster as both - the drying heat source and supplemental atomization energy. This way, particle diameters down to the nanometer range may be acquired. Hypulcon

Hypulcon

With its remarkably fast drying speeds and therefore low impact on the feed contents, even extremly sensitive materials such as Lactobacillales can be processed.

-

Typical Temperatures Inlet up to 300 °C, outlet 60 °C Evaporation Capacities 0.5 to 6500 kg/h (pure water base) Chamber Diameters Custom Heater / Atomizer Combined Hypulcon and 2-fluid nozzle system Powder Collection Blow-down, take-up, aero cyclone Options Bag filter, scrubber, pneumatic powder conveyor/cooler

-

Nozzle atomizer spray dryers with chamber panel heating, reaching temperatures up to 1000 °C. This allows for spray drying and thermal treatment such as activation, calcination or pyrolysis in one single step. Spray Heat Reactor

Spray Heat Reactor

Applicable to catalysts, superconductors, battery, magnetic and various compound materials.

-

Typical Temperatures Inlet up to 1000 °C, outlet 80 to 100 °C Evaporation Capacities 0.6 to 6 kg/h (pure water base) Chamber Diameters 200 to 300 mm Heater Types Electric Applicable Atomizers Two-fluid nozzle Powder Collection Blow-down, bag filter Options Combined Hypulcon and 2-fluid nozzle system

-

Lab scale dryers especially designed for use of our patented TwinJet nozzle series. For making finest powders below 20 micrometers in diameter. µGranulizer

µGranulizer

Well-suited for research and processing of e.g. battery materials, pharmaceuticals and catalysts.

-

Typical Temperatures Inlet up to 250 °C, outlet 70 to 100 °C Evaporation Capacities 1 to 1000 kg/h (pure water base) Chamber Diameters 300 to 5000 mm Heater Types Electric, gas (direct) Applicable Atomizers TwinJet nozzle Powder Collection Blow-down, aero cyclone, bag filter Options Nitrogen one-pass mode (1 kg/h model, inline mixing nozzle, filter cloth chamber (3 kg/h model)

-

Superheated steam sterilizer for refinement of foodstuff and others. Even while loading and unloading samples the steam atmosphere is kept in a closed cycle which makes the SK-1 very energy saving. SK-1

SK-1

-

Typical Temperature Up to 200 °C Chamber Diameter 380 mm Heater Types Electric Options Various sample trays and mixers