-

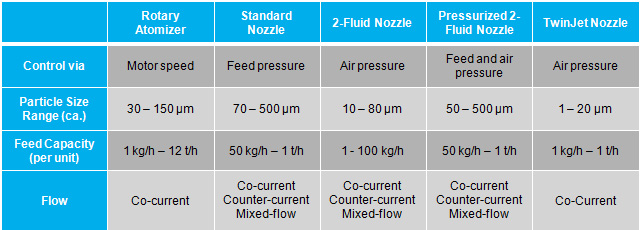

The atomizer of a spray dryer distributes the feed liquid to a mist of fine droplets with a high surface to volume ratio - essential for fast, accurate and gentle drying. Its design strongly influences the final product properties in terms of particle size & size distribution, shape, porosity, flowability and many more. Atomization

AtomizationThe Ohkawara rotary disc and spray nozzle atomizers can easily cover all types of feeds at flow rates from less than one kilogram up to several tons per hour and allow for dependable reproducibility and easy up-scaling. Feasible droplet sizes range from one single up to hundreds of microns in diameter.

-

-

This type of atomizer uses a vaned, serrated or perforated disc rotating at high speeds. The centrifugal energy provided by means of an electric motor or an air turbine drive translates into formation of a fine horizontal droplet spray. Rotary Discs

Rotary Discs

With rotary disc atomizers also highly viscous and abrasive feeds or feeds with very high solid content may be processed while always maintaining easy control and a homogenoeus spray. At present Ohkawara rotary disc atomizers are available in capacities up to 12000 kg/h.

-

Rotary Atomizer Units

M-Disc (patent)

Kessner Disc

Nozzle Vane Disc

Slit Vane Disc -

M-Disc

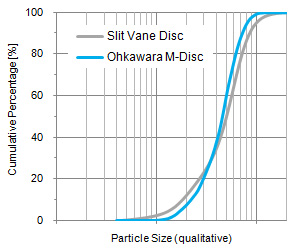

M-DiscThe curved teeth of the unique M-disc cause the feed liquid film to form a layer of uniform thickness over the entire height of the disc.

This results in a remarkably sharp droplet size and therefore sharp particle size distribution, compared to other disc types.

Narrow distribution of the atomized droplets will not only result in perfect flowability of the acquired powders, but also increase your overall yield.

-

By comparison, nozzles convert pressure energy provided by the feed pump into kinetic energy resulting in single droplets. With exchangeable orifices nozzles can be adjusted to various operational conditions. Nozzles permit multiple atomizers in one single chamber and can therefore also cover largest capacities. Spray Nozzles

Spray Nozzles -

Standard Pressure Nozzle

2-fluid Nozzle

Air Assisted Pressure Nozzle (patent)

Twin Jet Nozzle RJ (patent)

Twin Jet Nozzle TJ (patent) -

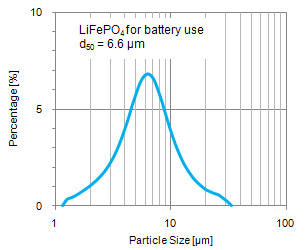

TwinJet-Nozzles

TwinJet-NozzlesThe newly developed RJ- and TJ-series TwinJet spray Nozzles cover the operating range of ultra-fine particles (single micrometer range) at both - low (RJ: 1 to 25 kg/h) and high (TJ: 25 kg/h to 1 t/h) feed rates in a single nozzle setup. Their patented two-step atomizing technology, using pressurized air to break the surface tension of the liquid, extends the working range to particle diameters unrivaled by conventional spray nozzles or rotary disc atomizers.

-

Operating Ranges

Operating Ranges